#611 610 World Meridian Venture Center Primary, 254, Beotkkot-ro, Geumcheon-gu, Seoul, Korea

Tel: +82-2-2113-8268

Fax: +82-2-2113-8269

Email: bizpeer@bizpeer.co.kr

Yeongnam branch

32, Bieum-ro 4beon-gil, Seongsan-gu, Changwon-si, Gyeongsangnam-do, Korea

Tel : +82-55-252-3560

Fax : +82-55-252-3561

copyright 2015 BIZPEER.

all rights reserved.

design by itlife.

HAZOP

The hazard analysis method is divided into Inductive method and Deductive method. Inductive method includes FMECA, FMEDA, HAZOP, QRA etc. and Deductive method includes FTA method.

HAZOP means ‘Hazard & Operability Studies’ which is the method for verification activity that inputs the specialist (Chairman and Scribe), reviews and analyzes the hazard to prepare a report.

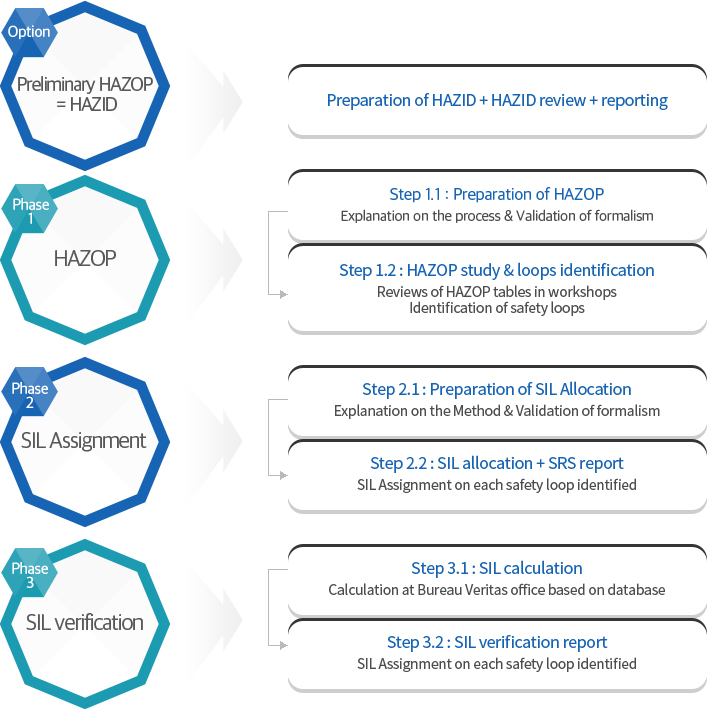

HAZOP methodology

Related Standards

- IEC 61508 : Industrial STD

- IEC 62061 : Machinery

- IEC 61511 : Process

- IEC 61513 : Nuclear

- EN50126,50128,50129 : Railway

- DO-178,254 : Airborne System

Hazard Deviation Table

| Parmeter | None | Part of | Early | Late | More | Less | Other Than | Reverse | As Well As |

|---|---|---|---|---|---|---|---|---|---|

| Interface | |||||||||

| Time |

For what purpose is HAZOP Study (Review) used?

To prevent various hazard situations that may occur while operating and remove them in advance through verification activity to analyze and remove the hazard source before plant construction or large-sized system manufacturing and operation

Hazop Category

- Natural and Environmental Hazards

- Created(Man made) Hazards

- Infrastructure Hazards

- Fire and explosion Hazards

- Health Hazards

Considerations for HAZOP Study

- Start-Up

- Shutdown

- Normal Operation

- Degraded mode of operation

- Maintenance/isolation/inspection

HAZOP Table

| ID | Parameter | Deviation | Possible Causes | Scenario | Conse quencos | S | F | C | Existing means / Safety barrier | S1 | F1 | C1 | Recommendations & Actions | Responsible | No |

|---|