#611 610 World Meridian Venture Center Primary, 254, Beotkkot-ro, Geumcheon-gu, Seoul, Korea

Tel: +82-2-2113-8268

Fax: +82-2-2113-8269

Email: bizpeer@bizpeer.co.kr

Yeongnam branch

32, Bieum-ro 4beon-gil, Seongsan-gu, Changwon-si, Gyeongsangnam-do, Korea

Tel : +82-55-252-3560

Fax : +82-55-252-3561

copyright 2015 BIZPEER.

all rights reserved.

design by itlife.

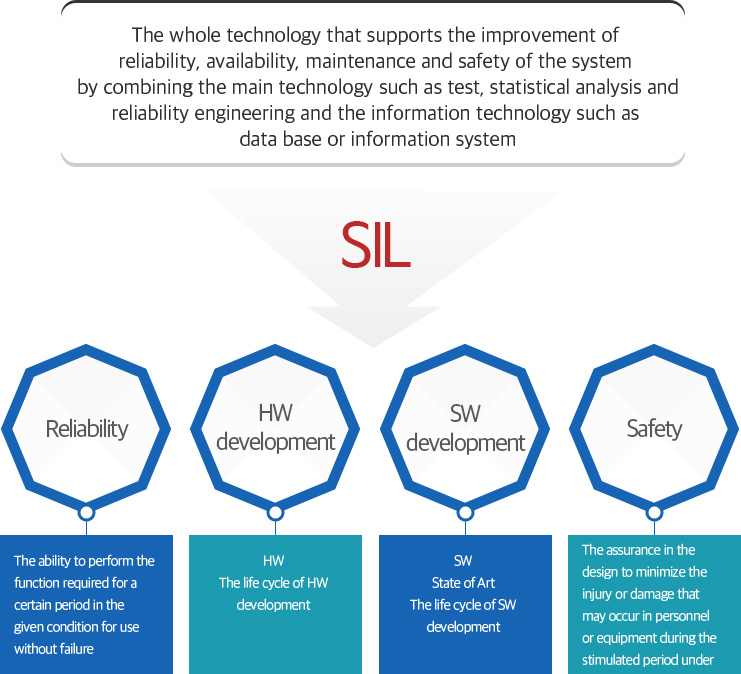

SIL

SIL(Safety Integrity Level)

SIL is the abbreviation of Safety Integrity Level, which is the technology that predicts from the first concept design of the system to the disposal and grafts the design and production and also the system engineering technology that collects, analyses the test and operation data and builds a database and carries out the estimation and analysis activity by RAMS element and finally secure the best product quality and safety by deriving a plan for design support/evaluation and design improvement and measures.

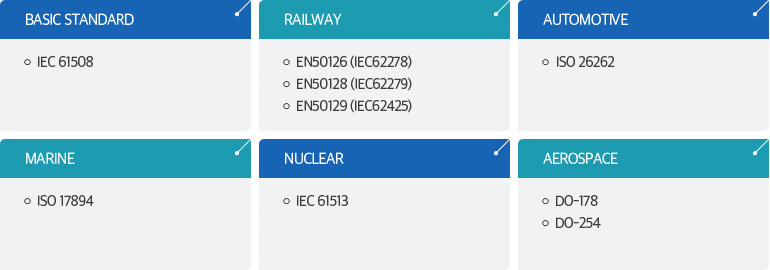

SIL applies IEC 61508 as basic standard to each industry differently. The technical and procedure requirement related to the analysis, design, implementation, test and maintenance activity necessary for securing the safety is applied differently by safety integrity level by applying IEC 61513 for Nuclear, and DO-178 & DO-254 for Aerospace, EN50126 (IEC 62278), EN50128 (IEC 62279) and EN50129(IEC 62425) for Railway, and ISO 26262 for Automotive, and ISO 17894 for Marine industry

SIL standard by industrial area

SIL Expectation Effect

SIL needs the selective management for the safety and the substantial investment but improves the competitiveness through reliability/safety management.

Extension of safety problem solving area

- The development of science and technology provides the wide range of technical solution, with the accelerated product innovation cycle

- According to the expansion of digital convergence, lots of responsibility for functional safety is allocated to the digitalized equipment.

- It brings the result that the area of problem solving related to the safety is getting wide.

The Past

- The verified technology was used to accomplish the safety

- Mechanical/Electro-Mechanical safety system in the majority

- Single mode system in the majority

- “Hard-Wired”safety

- Centralized safety structure

The Present

- In case of application of new technology, a high probability to decrease the safety

- Electronic/SW based safety system is spread rapidly

- Extension of multimode and single system

- Network/IT convergence/intelligence based safety

- The distributed safety structure

- High level design tool

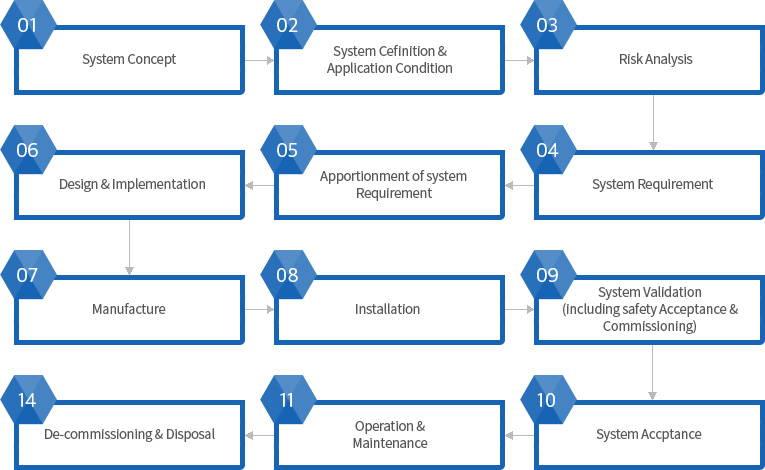

System Development Lifecycle

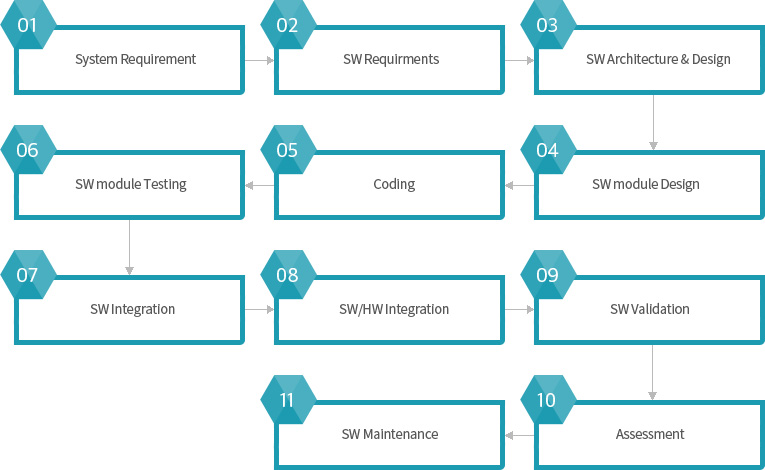

S/W Development Lifecycle

Application of safety engineering

System /SW safety engineering

- Risk analysis

- Application of recommended development technique

- Safety proved

The era of ICT & Convergence

- Increase of complexity for development/management

- Increase of development cost

- Issue to prove the safety

System Development

- Risk analysis based system development - System Engineering

- SW system development - State of Art

- SDLC - Railway/Automotive/Nuclear etc.

SIL proof demand

- Client (Domestic/Overseas) - Required to obtain a SIL certificate

- Increase of industry for SIL certificate - Now spreading to all kinds of industry that needs the safety such as railway, automotive, chemical plant, power plant, general product etc.

Safety Integrity Level, SIL

- Safety Integrity Level means the low risk level provided by Safety Function and the measurement for the performance required for a safety instrumented function (SIF)

- The safety integrity rating is defined in a little different shape according to the standard for each safety function (SIL1 ~ SIL 4, SIL A ~ SIL D, PLa ~ Ple, CAT1 ~ CAT4 etc.) and each rating defines the allowable level of dangerous failure of the corresponding function.

- The higher the figure of SIL grade is, the higher the safety integrity level is. (The level of safety management should be also high.)