#611 610 World Meridian Venture Center Primary, 254, Beotkkot-ro, Geumcheon-gu, Seoul, Korea

Tel: +82-2-2113-8268

Fax: +82-2-2113-8269

Email: bizpeer@bizpeer.co.kr

Yeongnam branch

32, Bieum-ro 4beon-gil, Seongsan-gu, Changwon-si, Gyeongsangnam-do, Korea

Tel : +82-55-252-3560

Fax : +82-55-252-3561

copyright 2015 BIZPEER.

all rights reserved.

design by itlife.

ISO 26262(ASIL)

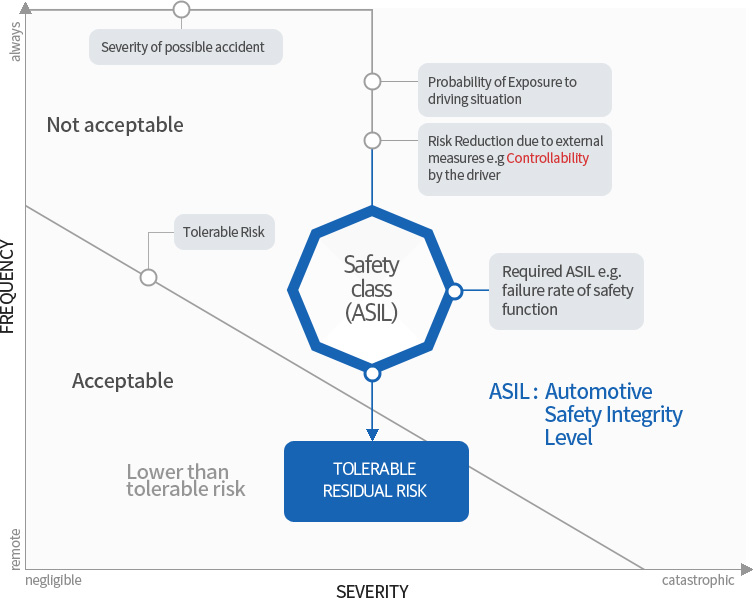

This defines the requirements for systematic method and procedure so that electric/electronic system (product) in the automotive industry can be developed and supplied to meet the original function as well as the related safety requirements (to accomplish the goal to reduce the acceptable residual risk in the society).

CMMI (Capability Maturity Model Integration) and ASPICE (Automotive SPICE) provides the basic frame for systematic and continuous improvement as a model to measure and assess the process maturity of organization or project basically.

Thus, to realize the ISO2626, the CMMI or ASPICE based process should be built and operated in the electric/electronic system area.

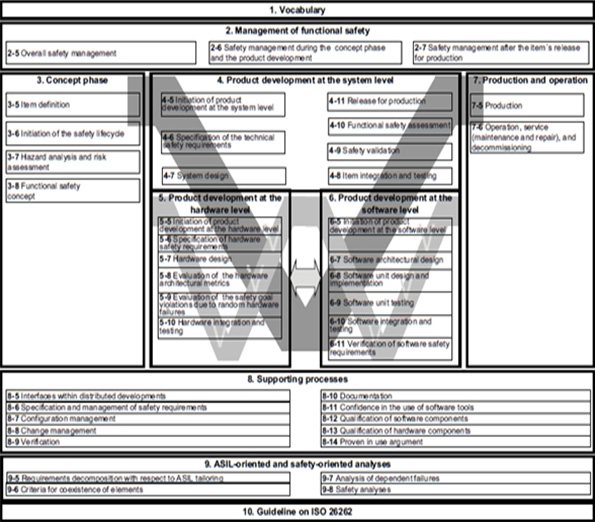

The configuration of ISO26262 is as follows

ISO26262 (ASIL) based product development

ASIL is divided into total 4 grades (A, B, C & D) and as shown in the figure below, the grade is given based on the severity, probability of exposure and control ability.

S : Severity, E : Probability of Exposure, C : Controllability

| C1 | C2 | C3 | ||

|---|---|---|---|---|

| S1 | E1 | QM | QM | QM |

| E2 | QM | QM | QM | |

| E3 | QM | QM | A | |

| E4 | QM | A | B | |

| S2 | E1 | QM | QM | QM |

| E2 | QM | QM | A | |

| E3 | QM | A | B | |

| E4 | A | B | C | |

| S3 | E1 | QM | QM | A |

| E2 | QM | A | B | |

| E3 | A | B | C | |

| E4 | B | C | D |

Severity

| S0 | S1 | S2 | S3 |

|---|---|---|---|

| No Injuries | Light and moderate injuries | Severe and life-threatening injuries (Survival probable) | Life-threatening injuries(survival uncertain), fatal injuries |

Probability of Exposure

| E0 | E1 | E2 | E3 | E4 |

|---|---|---|---|---|

| Incredible | Very low probability | Low probability | Medium probabillity | Hight probabillity |

통제력(Controllabillity)

| C0 | C1 | C2 | C3 |

|---|---|---|---|

| Controllable in general | Simply controllable | Normally controllable | Difficult to control or uncontrollable |

ISO26262 is not applied to the following cases.

- The system installed for the vehicle for disabled driver or special purpose

- The system or components before issue date of ISO26262

- Unless the malfunction of E/E safety related system is not the direct cause, the cause source (electric impact, fire, smoke, heat, radiation, toxicity, combustibility, corrosion, energy emission etc.)외

Advantage of ASIL

ASIL allows the user to improve the safety of development product as it can prevent the systematic faults and detect and control the potential faults by performing the safety activities to ensure the functional safety of electric/electronic system.

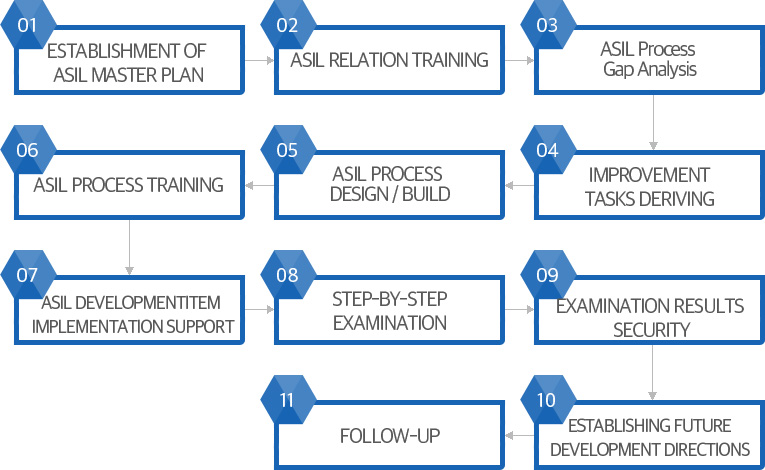

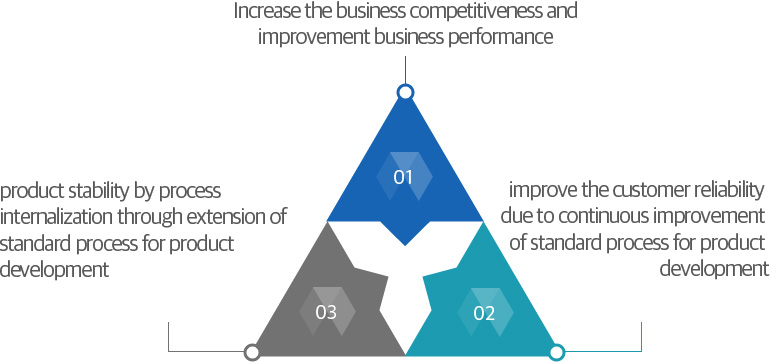

Consulting Methodology

BIZPEER, possesses its own consulting methodology in ASIL section of automotive area based on SIL certification consulting experience which allows to develop the AIL based product and certification consulting to meet the demand of customer.