#611 610 World Meridian Venture Center Primary, 254, Beotkkot-ro, Geumcheon-gu, Seoul, Korea

Tel: +82-2-2113-8268

Fax: +82-2-2113-8269

Email: bizpeer@bizpeer.co.kr

Yeongnam branch

32, Bieum-ro 4beon-gil, Seongsan-gu, Changwon-si, Gyeongsangnam-do, Korea

Tel : +82-55-252-3560

Fax : +82-55-252-3561

copyright 2015 BIZPEER.

all rights reserved.

design by itlife.

ASPICE

SPICE is composed of total 53 processes of which ASPICE selected 31 processes.

In particular, HIS evaluates the improvement and ability of supplier focusing on the 15 core processes.

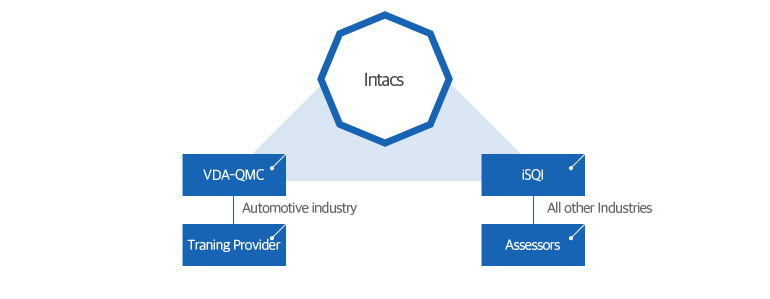

ASPICE assessor is managed by INTACS (International Assessor Certificate Scheme: independent non-profit corporation).

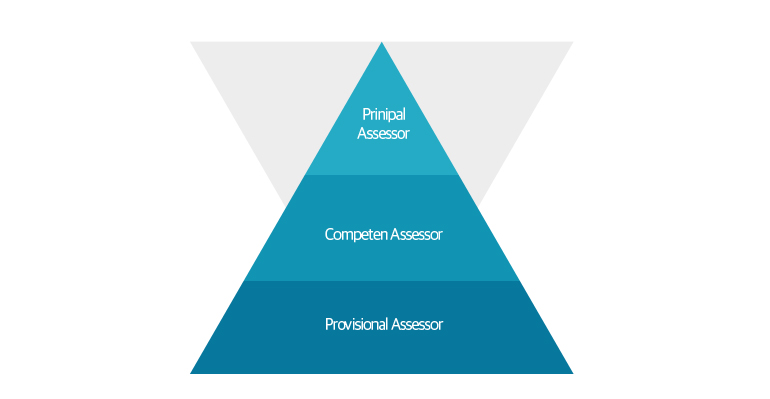

The assessor rating is managed by dividing into three types.

ASPICE (Automotive SPICE)

Based on ISO 15504, as automotive domain specific system and SW process improvement and ability evaluation model established by Automotive Special Interest Group (SIG) of Europe, the major vehicle manufacturers (AUDI AG, MBW AG, Daimler Chrysler AG, Fiat Group Automobiles SpA, Jaguar Land Rover, Dr. Ing. H.c.F. Porsche AG, Volkswagen AG and Volvo Car Corporation) are participating.

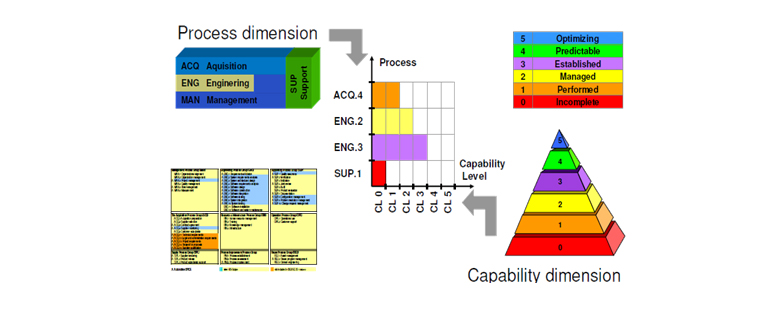

ASPICE model is composed of 2D : process dimension and capability dimension, which is divided into CL (Capability Level) and ML (Maturity Level) and the maturity level is evaluated by 0~5 grades. ASPICE performs the assessment based on PAM (Process Assessment Model) V2.5 and the reference model, PRM (Process Reference Model) includes ISO 12207, 15288, CMMI etc.

Composition of ASPICE Model

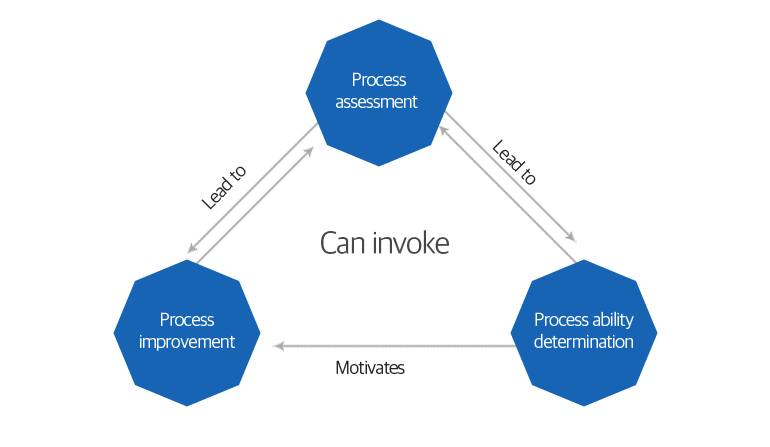

For what purpose is the ASPICE used?

ASPICE is used for process assessment, process improvement and process ability determination for the improvement of automotive system and SW process.

Expectation Effect of ASPICE

| Type | Immature process organization | Mature process organization |

|---|---|---|

| Process | unstable and repeated the trials & errors

|

The process in the level of organization and execute according to the planned process

|

| SW quality |

Unpredictable

|

Predictable

|

- The defect and development period will be reduced and the cost will be saved and the profit of enterprise will be maximized

- As the level of CMMI/ASPICE increases, the effect will be more outstanding.

| Benefits | Level 1-2 | Level 2-3 | Level 3-4 |

|---|---|---|---|

| Defect reduction rate | 12% | 40% | 85% |

| Development period reduction rate | 10% | 38% | 63% |

| Cost reduction rate | 8% | 35% | 75% |

| Schedule deviation | 145% | 24% | 15% |

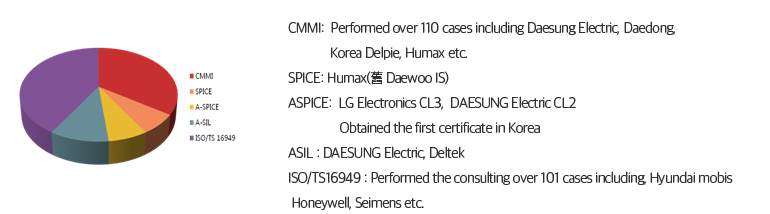

Why BIZPEER?

Domestic model based PI consulting pioneer

- 1999 : Started the assessment advice for CMM Level 2~3 (POSCO ICT)

- 2002: Started CMMI based PI consulting (HANJIN Information Communication)

- 2012: Started the ASPICE-based PI consulting (DAESUNG Electric)